As a leading engineering company, Geostock is involved in all underground storage project stages (new projects or storage facilities in operation), techniques (mined caverns, salt caverns and porous media such as aquifers and depleted fields) and skills.

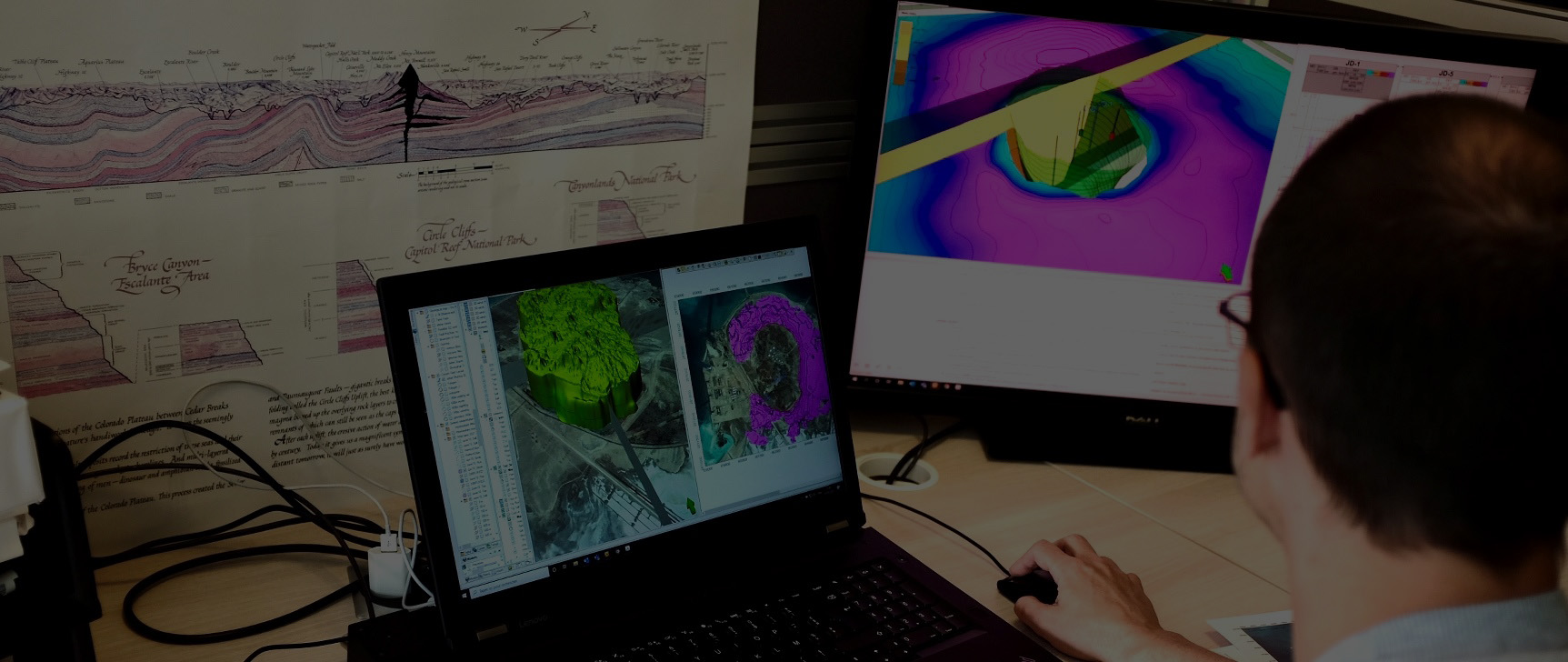

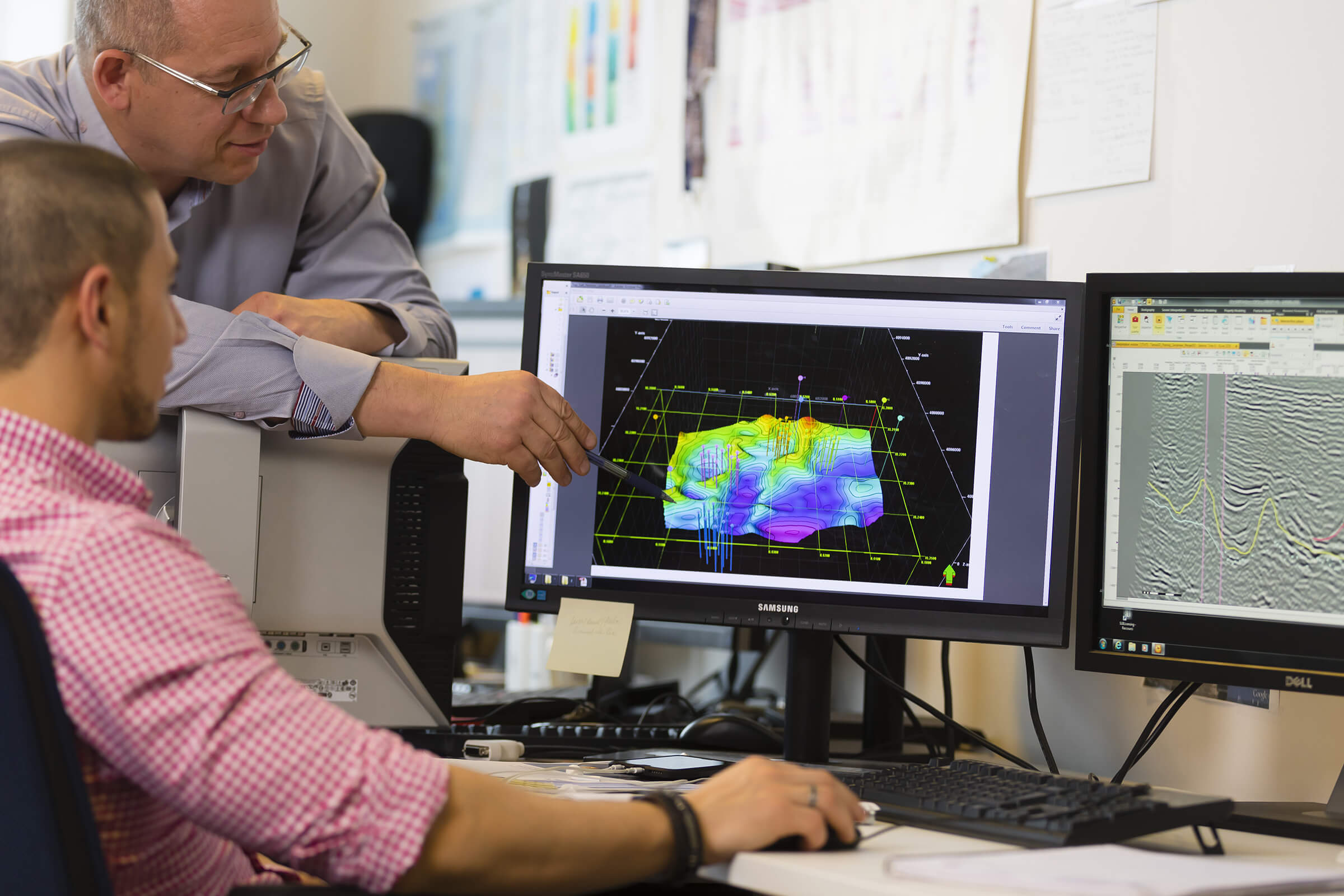

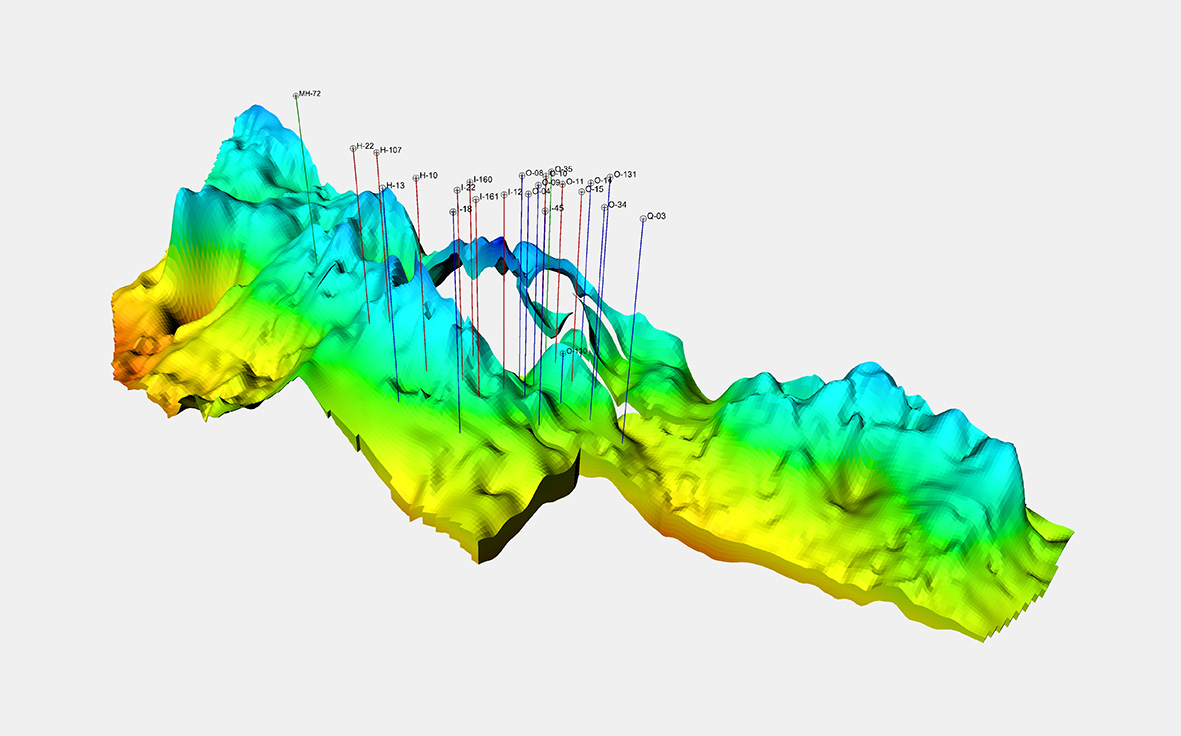

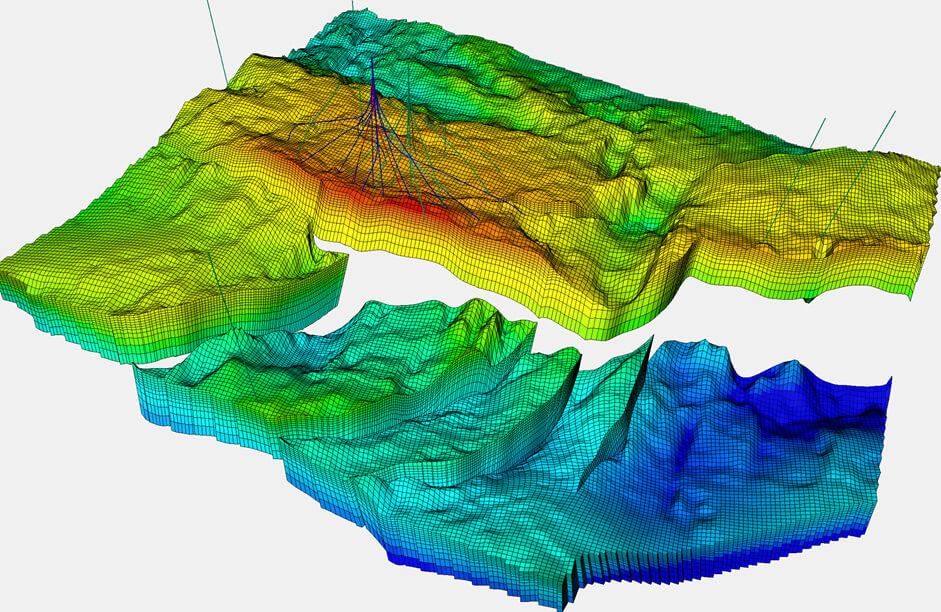

Geostock encompasses the underground skills (geophysics, geology, hydrogeology, geotechnics, underground civil engineering, drilling, reservoir engineering, solution mining), as well as surface facility skills (process, rotating machines, compression, piping, pipe networks, surface civil engineering, electricity, automation, instrumentation, anti-corrosion, materials).

More generally, the company possesses all the cross-cutting skills relating to underground storage (integrity test of boreholes before leaching, and tightness test of caverns before commissioning, administrative engineering, safety and environment).

GEOSTOCK continues to offer engineering services tailored to each project phase.

Preliminary projects are crucial stages in which the outline of future projects is sketched and future structuring options are chosen.

Pre-feasibility studies, generally conducted on the basis of available data, whether public or acquired from other players, result in a preliminary design (orders of magnitude for storage depth and flow rates) and a description of the ensuing phases.

Feasibility studies are usually based on initial geological investigation (a limited number of drilling operations, accompanied by in situ and laboratory tests) serving to determine expectations and specify acquisition methods. Investigation works are usually contracted directly by the client, with Geostock helping out by selecting contractors and supervising them in the field. Geostock is responsible for interpreting the results. A feasibility report is produced to refine the design (bottom and surface) but remains preliminary. A project cost is assessed (AACEI Class 4 or 5), together with an initial construction schedule. The following steps are described, beginning with possible additional site investigation.

Additional site investigation obeys the same principles as initial investigation, with Geostock setting out objectives, identifying the required investigation work and specifying methods. This stage may include drilling, seismic studies, in situ and laboratory tests.

The next step is to prepare a basic design, based on initial investigation and, frequently, additional investigation. Geostock designs the underground and surface facilities of the storage. The scope of the study is specified before the study is initiated so that Geostock can focus its design studies on facilities directly associated with the underground storage (well equipment if applicable, product treatment at the inlet or outlet, metering, compression, etc.) or, at the client’s request, extend its studies to auxiliary facilities (loading arms for transport by trucks, wagons or ships, heaters in case of reception of refrigerated ships, pipeline links, buildings, etc.). For salt caverns, Geostock also studies the surface facilities required for leaching, including water supply and brine discharge.

The basic design report includes descriptions, technical specifications, drawings, equipment lists, PFD and P&ID. A Class 4 or Class 3 cost estimate is proposed, along with an updated construction schedule and risk analysis. The exact list of documents is discussed with the client when the offer is submitted.

The tender documents for the construction of the storage facility form the complete technical documentation for the procurement of the detailed engineering, procurement and construction (EPC) contracts. At the client’s request, Geostock completes the basic design file to produce a front-end engineering design (FEED) file, which may include specific detailed studies, blank price lists, and additional technical specifications.

Geostock assists its clients in the planning permission process, an aspect that needs to be initiated at an early stage so as to not slow down project development.

Geostock can provide risk and safety studies, whether or not they are included in the design files. Geostock masters standardised FEMCA, HAZID, HAZOP and SIL procedures.

Geostock can provide its clients with light underground storage project management teams, typically taking the form of one or two people, possibly working at the client’s site. The company can also mobilise technical experts to support the projects of its clients.

For nearly 60 years, Geostock has been involved in the underground storage of a wide range of products, including liquid hydrocarbons (crude or refined), liquefied hydrocarbons (liquefied petroleum gas), gaseous hydrocarbons (natural gas in particular), carbon-free energy (hydrogen, compressed air) and carbon dioxide (CO2). Geostock has developed its concepts and practices through this engineering work. Patents have been filed and digital technologies have gradually made their way into design tools. The process is systematically based on a real partnership with the client as part of a long-term relationship of trust. Geostock engineering is also bolstered by virtuous synergies with the company’s other fields of work, including consulting, construction management and operation. Feedback from each activity nurtures the other activities, while the circulation of ideas, know-how and personnel mobility has allowed to forge peerless skills levels.